Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

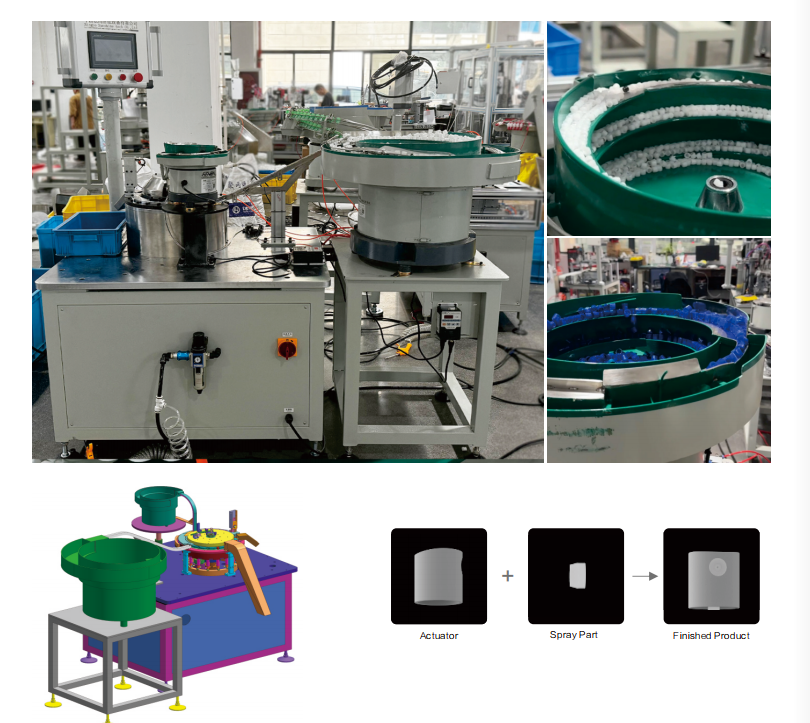

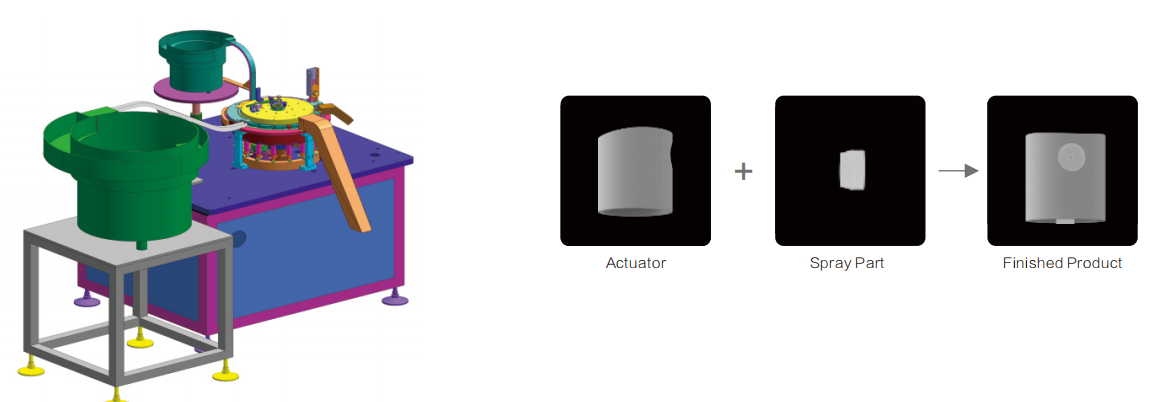

SR-MSM-04 2-Piece of Spray Film Automated Assembly Machine

Description

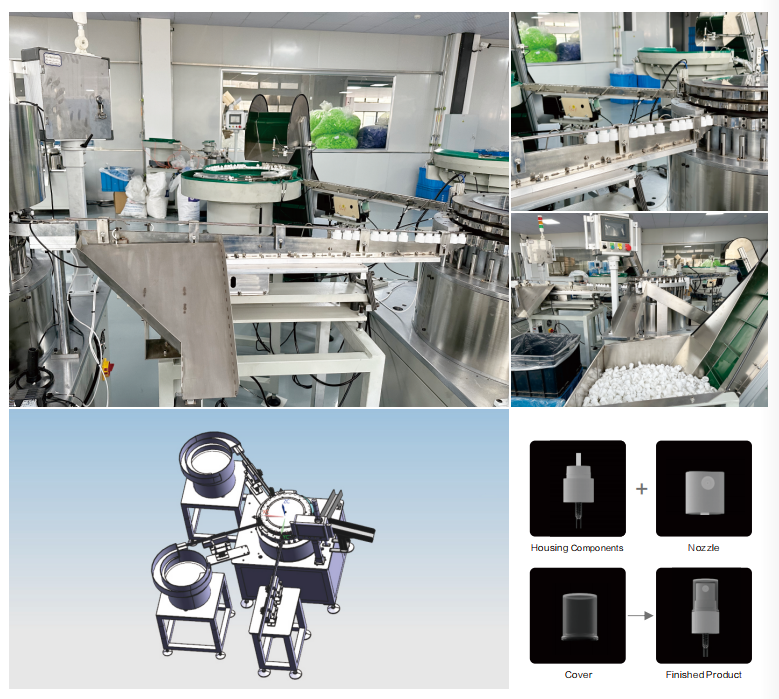

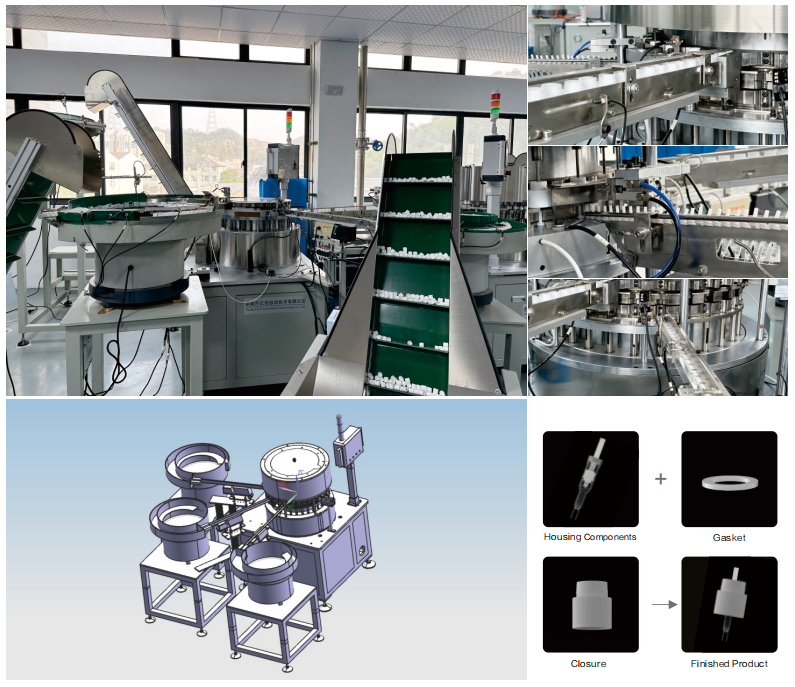

The Actuator automatic two-piece spray assembly machine is a precise and efficient system designed for the precise assembly of mist sprayer components. This advanced machine is an integral part of the mist sprayer manufacturing process, ensuring high quality and consistent output. It integrates a range of mechanisms, including an Actuator feeder and a Spray Par feeder.

Product Specification

| Main Component Configuration List | |||

|---|---|---|---|

| Project | Brand | Place of Origin | Remarks |

| PLC | Delta / Siemens | Taiwan, China / Germany | Customize |

| Servo Motor | Delta | Taiwan, China | Customize |

| Stepping Motor | Leisai / NBNCKJ / Inovance | China | Customize |

| Frequency Conversion Motor | Limin | China | Customize |

| Touch Panel | Weinview | China | Customize |

| Module | Dazzle | China | Customize |

| Guide Rail | Hiwin | Taiwan, China | Customize |

| Cylinder | Airtac / SMC / Festo | Taiwan, China / Japan / Germany | Customize |

| Barometer | Keyence | Japan | Customize |

| Non-Standard Component | Customize | China | Customize |

Product Features and Advantages of 4-piece Mechanical Assembly Machine for Pistons

1. Advanced Vibration Disk Feeding: The O-ring feeding vibration disk ensures that components are fed smoothly and consistently, reducing the chances of jamming and downtime.

2. Touch-Screen Operation Table: The user-friendly touch-screen interface simplifies machine operation, allowing for easy adjustments and monitoring of the assembly process.

3. Compact Design: With a total height of about 1.9 meters, a length of 1.1 meters, and a width of 1.4 meters, this machine is designed to fit efficiently within manufacturing spaces while still offering robust performance.

4. Inspection Station: An integrated inspection station ensures that each component meets stringent quality standards before moving to the next stage of assembly.

5. Multi-Mechanism Integration: The machine includes mechanisms for piston feeding, spring feeding, bottom valve feeding, and discharge, ensuring a comprehensive assembly process.

Benefits

1. Increased Productivity: By automating the assembly of pistons, manufacturers can achieve higher throughput, meeting increased demand without compromising on quality.

2. Cost Savings: Automation reduces labor costs and minimizes material waste, leading to significant cost savings over time.

3. Quality Assurance: Integrated inspection and testing mechanisms ensure that only components meeting exacting standards are used, enhancing the overall reliability of the final product.

4. Space Efficiency: The compact design of the machine allows for optimal use of floor space in manufacturing facilities, enabling more efficient layout and operations.

5. Enhanced Competitiveness: By leveraging advanced technology, manufacturers can stay ahead of the competition with superior product quality and production efficiency.

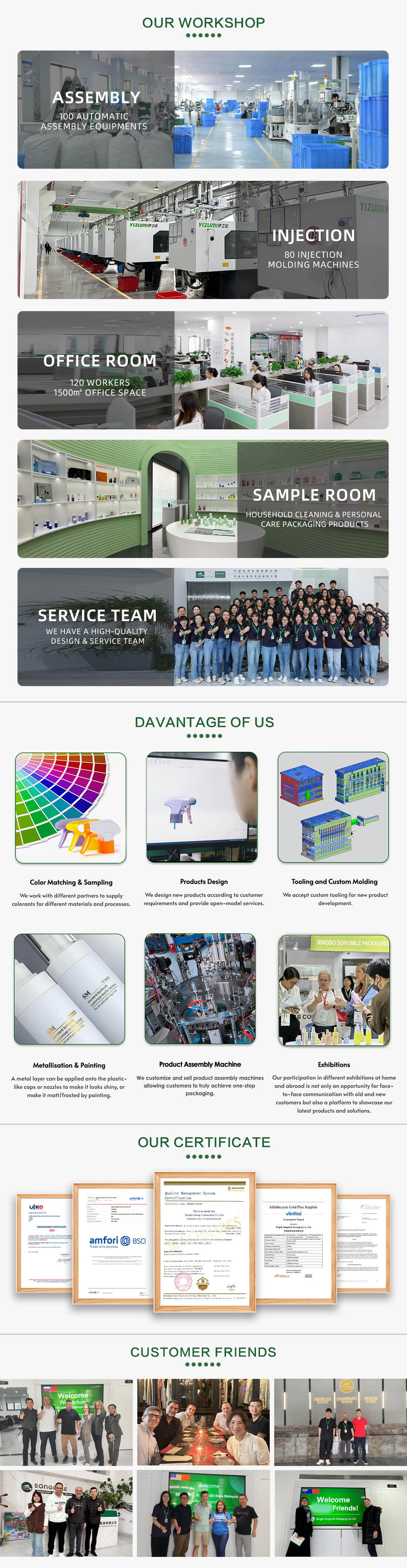

Why Choose Us?

1: Are you a trade company or an manufacturing factory?

We are the Industry and trade integration company, we have our own manufactory.

2: How to get a quotation and start business relationship with your company?

First we need the photos of the item which you need the machine to assembl it, then we will send a information collection sheet to you, after all the informaton confirmed, we will send our quotation to you along with the delivery time and design drawing.

3: What's the minimum order quantity?

Our MOQ is 1 set of machine or one production line, we also sell product's mould as package, more quantity more discount.

4: Can you make customised automatic assembly machines(line)?

Yes, we can, and we are experienced in manufacturing customised automatic assembly machines (line).

5: What's the delivery time?

Normally the delivery time is 2-3 months.

6: How about the payment terms?

50% in advance,40% after machine finished, and balance 10% before delivering. T/T, Irrevocable L/C at sight are all acceptable

7: Do you provide on-site installation and Commissioning services?

Yes, we can provide on-site installation and Commissioning services, but the buyer have to bear the trip air tickets, accommodation, and labor subsidies,etc.

Please let me know if you have any questions, don't leave silently...